Melting at each die casting machine enables us to offer a wide range of Aluminum, Zinc, and Zinc-Aluminum (ZA) alloys to meet your unique specifications.

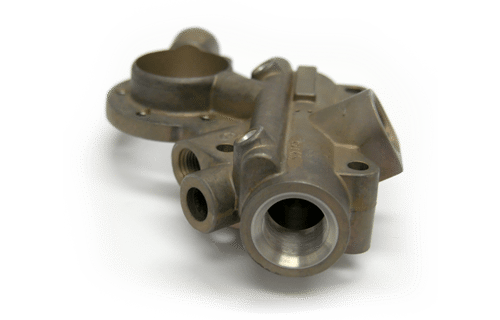

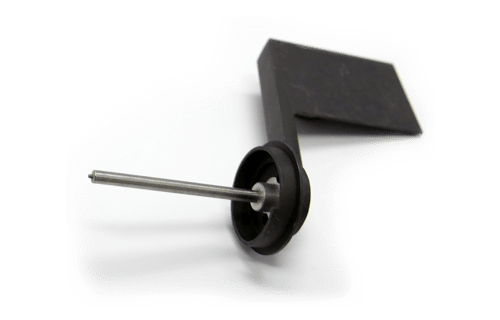

We are one of a few companies with extended casting range capabilities. We have die cast machines sized from 250 to 1,650 tons and can produce parts that range in weight from fractions of an ounce to more than 75 pounds. Our extensive experience with pressure-tight castings and molded-in inserts, bushings and bearings takes the uncertainty out of any project we accept.

Hyatt Die Cast also employs a number of techniques to ensure efficiency on every die cast project. Our facility’s hot oil temperature control units and closed-loop die cast cooling system regulate the environment during casting, and a central vacuum system can be used to minimize porosity.

We meet the highest standards for precision with a mix of modern and time-tested methods. Our shot monitoring system, which analyzes real time data from the casting machines, ensures the process remains within its defined parameters.

Automated systems are utilized to ladle metal, lubricate the die and extract the finished casting. Finally, an on-site x-ray machine allows our teams to monitor and control foundry conditions in real time.

Contact us about your die casting needs.

Get Started