Hyatt Die Cast & Engineering Corporation is a family-owned and operated manufacturer of Aluminum, Zinc and ZA alloy die castings. We are a woman-owned small business and our industry-leading operation has created precision solutions for our clients’ unique needs since 1956.

As your “partner in producibility,” our engineers will work with you to turn your design into the best die cast part possible. Our client base includes Fortune 100 companies and customers in the Aerospace, Defense, Medical, Gaming, Electronics and Communications industries.

Hyatt’s two Southern California facilities include:

- 150,000 square feet of manufacturing space

- Fully equipped machine shop with more than 25 CNC machines

- Complete tool and die shop

- High-pressure die casting machines ranging from 250 to 1,650 tons

- 640 foot semi-automated powdercoat line with prewash, primer, topcoat & cure stations

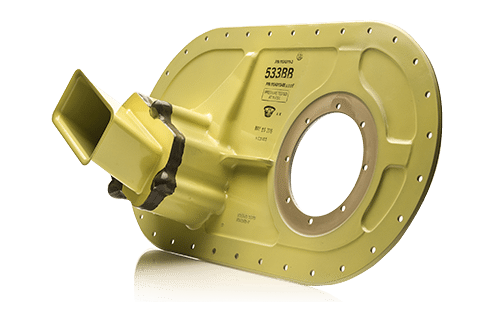

Our casting size capabilities range from less than one ounce to over 75 pounds. We accept short run productions and support product service and spares requirements. Orders can be received electronically and complete secondary processing is available.

Hyatt’s other value-added services include in-house powder coating, assembly, pressure testing, packaging and much more.

Our Quality System is AS9100 Rev D and ISO 9001:2015 certified and we are ITAR and EAR registered for defense-related production.

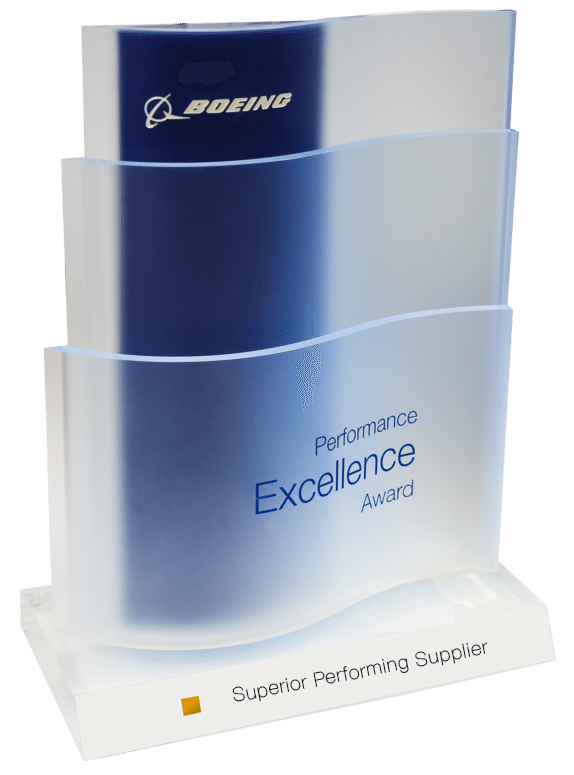

Awards & Recognition

Hyatt Die Cast has been recognized by our industry and our community with multiple commendations. We have earned Boeing’s Supplier Excellence award for quality and delivery performance for six consecutive years, as well as the Cubic Supplier Achievement Award for exceptional performance.